When the Motor Company released the new Milwaukee-Eight powerplant in 2017, it arrived with big promises, among them more power and torque. Two of the standout points of the new engine was the move back to a single-cam design and the use of a four-valve head setup.

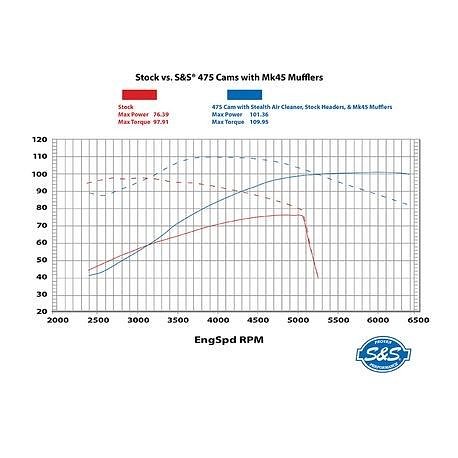

But then S&S came out with some cams and the game changed. The gains that can be had with an M8 by adding a drop-in cam are substantial, on par with what you would get out of a big bore plus a cam in older Twin Cams. Color me interested.

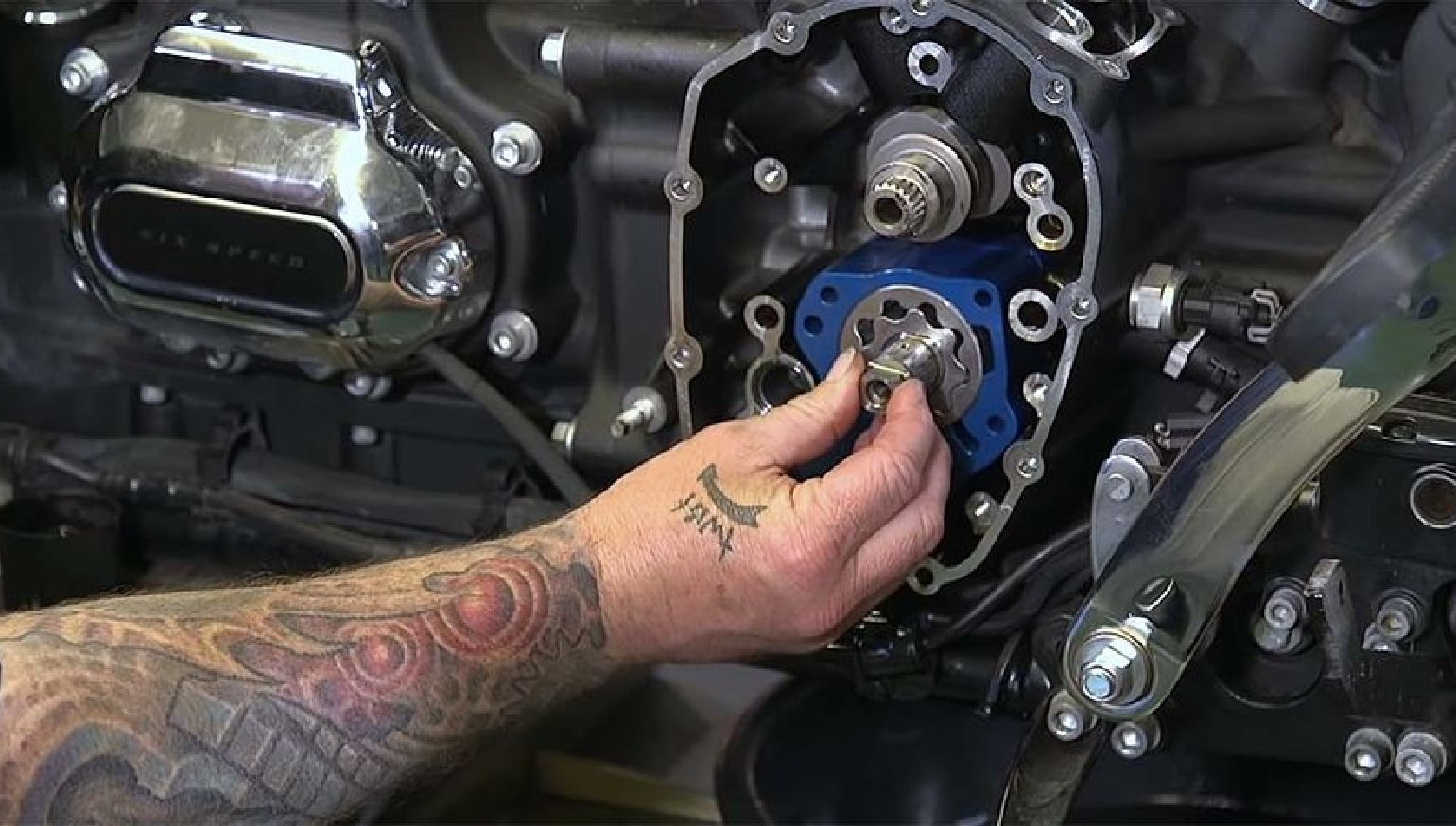

In the video above, we walk you through an M8 cam install step by step.

- Remove gas tank, intake and exhaust

- Slide pushrod covers up, find overlap on rear cylinder, cut pushrods loose, repeat on front cylinder

- Remove tappet covers and lifters

- Remove cam cover, remove cam tensioner and cam sprockets

- Slide off cam plate, cams and oil pump

- Replace inner cam bearing with new bearing (use JIMS tool)

- Assemble and lube oil pump and install

- Install cam and cam plate

- Install cam sprockets, chain and cam chain tensioners

- Install lifters, tappet cuffs and tappet blocks

- Install pushrod, covers, do pushrod adjustment front and rear cylinders

- Install cam cover, exhaust and intake

The cam isn't solely a magic bullet though. You will need to have some accompanying hardware to take full advantage of the M8's capabilities. Any time you do motor work you need to have a good flowing intake, exhaust and the ability to tune said machine. For this particular application S&S Cycle had just what we were looking for in a complete cam kit as well as intake and exhaust.

Now, you could just slap a cam in and re-use your stock oil pump, plate and lifters, but why go to the trouble of doing all that work and not use the best components? S&S's complete cam kit offers a number of cam choices. We went with a 475C kit because it works well for an otherwise stock engine, specifically stock compression. And I tend to stay away from gear drive cams with stock Harley bottom ends, the reason being crankshaft runout. You need .003 or better runout to run gear drive cams and H-D's spec is somewhere around .012, meaning that even if your crankshaft runout is within the .003, your flywheels could potentially move and still be in H-D spec but end up sheering the teeth off of your gear drive set-up.

With that being said we went with a gear drive 475 cam. The rest of the kit virtually replaces everything in the cam chest. The oil pump/cam plate combo provides independent scavenge sections for flywheel cavity and cam chest with increased flow capacity on both sides, removable passage plugs for servicing, debris screens in both pickups and an adjustable pressure relief valve. The S&S Cycle Quickee Pushrods make it possible to do this job without taking the rockers and rocker covers off your bike which really cuts time off the install. The tappet cuffs replace the plastic units in the stock motor and hold the S&S Premium tappets in their rightful place. We stayed with the American-made horsepower theme and used an S&S Stealth intake and 2 into 1 Sidewinder exhaust (check out our S&S Cycle Mini Teardrop Stealth Air Cleaner and S&S Sidewinder Exhaust for the Milwaukee-Eight install videos). Both a quality intake and exhaust are extremely important to getting results from the cam chest upgrade. And lastly and most importantly you need a tuner. It's really not an option to not use a tuner with this level of modification. We used a Dynojet Power Vision because of it's wide range of tuning options and availability of maps.

Don't be scared off by the install. It is a bit technical, but if you have a decent set of hand tools and are technically inclined you can get through it. You will need a JIMS bearing specialty tool, but beyond that this is definitely garage mechanic capable. The install video will be the same for both M8 Softail and Touring models, so take your time, reference the video, and enjoy your newfound horsepower.

Membership

Membership