This month we head down under to take a look at a homebuilt dustbin-faired T3 by an Aussie Guzzista. We then visit Brazil where the crew at SR Corse have torn down a Pierre Terblanche 900SS to perform a race-inspired redesign. Lastly, another Brazilian workshop, Benta Handmade, reveals their entry into the Honda "Wing Crafters" project based on a CB1000R Neo Sports Café.

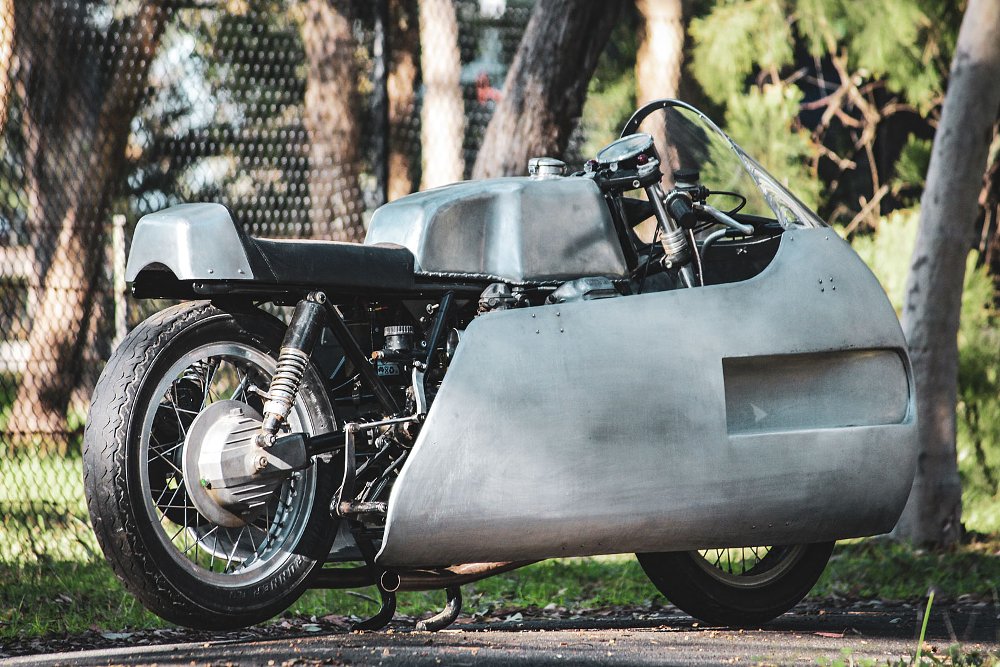

Kelvin Drummond Moto Guzzi T3 Dustbin

Teddy Roosevelt once said, "Do what you can, with what you have…" Those words ring true for the dedicated do-it-yourselfer.

From an early age, Kelvin Drummond of Victoria, Australia, found great pleasure in fixing things. "My dad was entirely useless mechanically. With no money or guidance, I learned to improvise," he recalls. "I once put a 160 cc Victa lawnmower conrod and bottom end bearing in a Bultaco 250 and rode it around like that for years!" After recognizing his interest in motorcycles, neighbors began gifting Kelvin non-running bikes, which he would breathe new life into.

Kelvin's interest in the internal workings of machinery led to him studying mechanical engineering at Melbourne University. Unfortunately, somewhere along the way his interest in motorcycles took a backseat to an obsession with Italian cars.

At the age of 40, Kelvin was drawn back to bikes. After finally acquiring a motorcycle license, he began the search for his first Moto Guzzi. Unable to locate what he wanted locally, Kelvin sourced not one but four Guzzis being sold by the estate of a deceased person in the United States. He shipped them to Australia. Today, he owns 10 of them.

It goes without saying that Kelvin works on his bikes himself, learning from online videos and trial and error. Along with servicing his Guzzis, he also modifies them to his liking. This dustbin-faired Moto Guzzi T3 was one of his original purchases from the States, and he built the bike entirely on his own.

"I am into the café racer aesthetic and was of the opinion that few bikes lend themselves more readily to this look than the big Guzzis," says Kelvin. "The inspiration for this build was a combination of Guzzi's racing history with dustbin-faired bikes and some photos of a 1960 Bultaco long-distance speed record bike I found."

This project was no walk in the park for Kelvin. With no welding or metal shaping knowledge, he quite literally threw himself into the deep end.

After stripping the T3 of its bodywork, Kelvin photographed the bare chassis and used tracing paper to draw the outline of what he wanted to build. From there he formed a wire buck using old fencing wire, which he wrapped in paper to create a template for the fairing. It was then just a matter of teaching himself how to make it.

"I discovered a video by an old guy in the UK on how he built aluminum fuel tanks," Kelvin recalls. "Somewhat uniquely, he would make the entire top section with one piece butterflied out. He then rolled and shaped the corners to meet it all up. There was no major hammering, no English wheel, or other fancy equipment. I was hooked and decided I would teach myself to do the same."

Along with shaping the aluminum for the bike's new tank, Kelvin had to learn to weld. "My father-in-law gave me a small oxy-acetylene torch some years ago and I read that these were well suited to aluminum welding," he says. "I just needed to learn how to do it. A lot of swearing later, I had a sealed tank."

The dustbin fairing came next and it, too, presented plenty of challenges. "I made a tool that put deep crinkles into the panels. By hammering the peaks of these with a heavy plastic-faced hammer, the material shrank into itself." This approach allowed Kelvin to form the basic shape of the nose before he bit the bullet and purchased an English wheel. "It helped a lot with the smoothing out, but there was also a lot of good old-fashioned hammer and dolly work," he says.

Kelvin built the dustbin fairing from three individual pieces of 1.2 mm alloy sheet metal. These were also welded together using his oxy rig, and an "even higher ratio of swearing to weld." He rolled the edges of the panels by hand and then added the cutouts for the cooling channels. Holding the fairing in place are aluminum round bar brackets aside from the main forward-facing support, which is steel. Wherever the body attaches to the fairing, Kelvin has added reinforcements to avoid cracks from excessive point loading. He also built the surround and the 2 mm polycarbonate windscreen that covers the cockpit.

Completing the T3's new attire is a small rear cowl made using the same technique as the fuel tank. Kelvin also put together the seat by shaping more aluminum. Being the resourceful chap that he is, he used an electric carving knife to shape a block of foam. The leather covering it was taken from an old leather jacket and he stitched it together using his wife's sewing machine. The work didn't end with the completion of the bodywork, though.

"I made everything that is custom on the bike, except a couple of brake hoses," says Kelvin. The laundry list of custom tweaks includes custom foot controls made using recycled stainless steel he had around his workshop, the handlebars were sand bent to form a swan-neck-style set of clip-ons, the electrical system is bespoke and pared back to the bare minimum, the exhaust headers were sand bent to look like a Yoshimura system, and the oversized speedometer is a repurposed Alfa Romeo 1750 Spider unit sitting in a custom surround.

Powering this Dustbin-fired T3 is a modified MKII Le Mans engine, which Kelvin stumbled across at a Land Rover mechanics shop. Sporting Dell'Orto PHF 36 carbs, it was built to power a Fiat 650 project but never made it that far. Kelvin's use of the big twin is much more appropriate and according to him it "pulls like a train!"

As a result of his hardships during this build, Kelvin has invested in several new tools to make his future endeavors easier. This Guzzi T3 should serve as inspiration for anyone wanting to tackle their own build. Without training or all the right tools, Kelvin's built his dream bike and that's an achievement worth acknowledging.

SR Corse Ducati 900SS road racer

Uruguayan ex-pat Sebastian Rochón has been tinkering with bikes since before he could get his license. His career as a bike mechanic has seen him working for the likes of Kawasaki, Bimota, and Ducati; during which time he completed several specialized training courses around Europe. Today he calls the Brazilian city of São Paulo home and it's where you'll find his SR Corse (Instagram) workshop.

Originally opened as a mechanical workshop 13 years ago, SR Corse now offers complete custom solutions to its clientele. His latest work is a showcase of both their ability to create bespoke components and his keen eye for design.

This motorcycle started out as a 1999 Pierre Terblanche Ducati 900SS. It belongs to a customer who attended one of SR Corse's customization training classes for youngsters looking to get into the field. "The owner asked me, 'What would you do with a 900SS?'" Sebastian recalls. "I answered him, telling him everything that I would do with the bike. He then asked me to take his 900SS and do everything I had described."

From a design standpoint, Sebastian has never been a fan of Terblanche's work. Mechanically, however, he felt the 900SS was a great performer, so this project focused on aesthetics. "Our design concept is always trying to create something timeless. A good fusion between past and future," he says. For this project, Sebastian found his inspiration in Cagiva's GP500; the motorcycle that bagged the manufacturer its first GP win (thanks to Eddie Lawson) and arguably one of the best-looking GP bikes ever built.

Sebastian's first step was to modify the 900SS front fairing. Opting for a half-faired design that would expose the Italian L-twin, he removed the entire lower half of Terblanche's design. In its place are svelte lateral panels that complement the lines of the 900SS fuel tank and chassis. The parts were modeled in CAD and then fabricated by merging 3D-printed components with fiberglass for greater strength. A classic round headlight replaces Terblanche's trapezoid design.

The transformation continued with the development of an all-new rear end. A custom subframe establishes a more aggressive, race-inspired stance. Sitting over the trellis chassis is a GP500-inspired cowl with another classic-looking round lens integrated into it.

SR Corse has established a reputation for building race-inspired motorcycles. Part of their approach is to hide the turn signals, which on this bike have been built into the custom license plate holder and recessed into the 3D-printed rearview mirror stems. In keeping with the era of this bike, Sebastian had his team fit the 900SS with a '90s Remus exhaust system.

In '99, this 900SS rolled out of Borgo Panigale sporting bright yellow paintwork. Since this project was inspired by Italian racing machines, SR Corse opted for a befitting Rosso Corsa red scheme. Race numbers and GP500 AGIP-inspired livery complete the look of this impressive 900SS.

Benta x Deus Ex Machina CB1000R Neo Sports Café

Honda Wing Crafters is a collaboration between Deus Ex Machina and Honda Brazil aimed at promoting the Neo Sports Café range as a platform for customization. To spearhead the initiative, Honda tasked four teams with customizing the bikes. Among them was Billy Pasqua and his workshop, Benta Handmade (Instagram).

Since its opening in 2016, Benta has amassed a portfolio consisting of more than 100 customs, including several for the likes of BMW, Harley-Davidson, and Triumph. The multidisciplinary team at Benta also has a long-standing relationship with the moto lifestyle brand Deus Ex Machina. To date, they've completed 10 bikes for the Deus "Mansion Of Munificence" in São Paulo, so their inclusion in Wing Crafters was a given.

The Benta team's goal with the 2024 Honda CB1000R was to celebrate the bike's roots while maintaining their trademark minimalistic styling approach. "Our idea was to bring out the richness of Japanese culture while also representing its contradictions," says Billy. "It's tradition versus modernity. Subtlety versus opulence. Discretion versus boldness."

Like all custom builds, this project wasn't without its challenges. In this case, it was a strict rule from Honda that the chassis should not be modified. This meant that anything Benta made for the bike would have to be held in place using existing mounts on the frame.

Before any work began, Benta performed a 3D laser scan of the CB1000R. The scan was then used to model millimeter-perfect parts onto the bike in a virtual environment. From there, they used either 3D printing or CNC technology to create the new parts.

Amongst the new components on this CB is a CNC-cut alloy cover for the single-sided swingarm rear wheel. The new belly pan, radiator shrouds, side covers, wheel hugger, and fork shrouds were printed in ABS plastic and lined with resin to increase rigidity. Benta also fitted the bike with a smattering of bolt-on accessories, including bar end turn signals and mirrors and a stumpy blacked-out muffler. To ensure the bike looked its best, everything has been finished to factory quality standards.

Curiously, the stand-out feature of this build isn't visible under normal lighting conditions. It was a concept Benta developed with artist duo Marmota vs Milky (Instagram). "Together we came up with a visual identity for the bike inspired by oriental elements and amulets used to make wishes come true, such as omamori and daruma, mixed with the universe of motorcycles," Billy explains. Taking inspiration from the neon signs of Tokyo and Japanese pop culture, the unique scheme uses UV-reactive paint, which reveals the Japanese symbols and shapes under blacklight. Unfortunately, it's an aspect of this build that many will never see. Nevertheless, Benta's interpretation of the CB1000R Neo Sports Café is a tastefully restrained triumph.

Membership

Membership